Anodizing treatments and aesthetic finishes

New Oxidal provides a wide range of anodizing treatments for metallic, magnesium, titanium and light alloys, satisfying the requests of its customers from a technical and aesthetic point of view

new oxidal in brescia

+40

years of

experience

Why choose

New Oxidal

360°

consultancy

We support our customers from the beginning of the project, selecting the most appropriate treatments for the alloys used and the intended use of the finished parts.

Certified

quality

We are a ISO 9001:2015 certified company, we work in accordance with the RoHs directive and we can make declaration of conformity for each batch.

Work

optimization

Thanks to the computerized management and monitoring systems, we continuously improve our workflows by guaranteeing the customer efficiency and speed in deliveries.

Environmental

protection

We use technologies and tools that allow us to optimize the energetic resources and to limit the release of harmful substances into the environment.

who we are

Our company

Founded in 1980 in Brescia, New Oxidal is a company specialized in the anodizing treatments of aluminium and magnesium and titanium alloys. We are one of the most advanced companies in the sector, partners of important industrial companies operating in various production sectors, from mechanics to automotive, from design to electronics.

New Oxidal

operates in various market sectors

Railway

Industrial

Aerospace

Lighting technology

Lighting

Nautical

Naval

Pneumatics

Closing

systems

Fashion and

design

Contract

Sports

technician

Automotive

Racing

Security

systems

what do we do

Anodizing treatments,

finishing pre-treatments

metal and alloys

The anodic oxidation or anodizing is an electrochemical transformation process of the surface of an aluminium object.

By placing the object on the anode by means of an electrolysis bath, the surface is transformed into an aluminium oxide layer, indelibly adherent, with a variable thickness depending on the treatment. This oxide layer, generated in a controlled way, confers corrosion resistance, surface hardness, thermal and chemical resistance and aesthetic finish to the anodized detail. The piece is therefore protected during its use from atmospheric agents, friction and wear, torsional tensions and it is aesthetically dressed.

The aluminium colouring is one of the steps of the anodizing treatment and is obtained by the use of Clariant® organic pigments. The colouring will remain forever because it is trapped in the surface.

The services offered

01

COLOUR PROTECTIVE ANODIZING AND AESTHETIC FINISHES OF ALUMINIUM (THICKNESSES FROM 5 TO 25 MICRONS)

It is a surface colouring of aluminium combinable with aesthetic treatments of polishing, glazing, sanding, brushing and engraving.

02

ALUMINIUM HARD AND SEMI-HARD ANODIZING (THICKNESSES FROM 25 TO 150 MICRONS)

It is an ideal treatment for precision aluminium parts, able to improve the chemical, thermal and mechanical resistance.

03

OXIDATION OF MAGNESIUM

It ensures high resistance to corrosion to the magnesium parts exposed to aggressive environmental conditions. The part can then be painted or glued.

04

CERAMIC ANODIZING OF ALUMINIUM (ALCE)

The ceramic anodizing provides high degree of protection to corrosion and thermal stresses to the aluminium part, while keeping it flexible.

05

CHEMICAL PASSIVATION

It is carried out on parts that must be protected from chemical and atmospheric agents, chromic passivation preserves the natural electrical conduction qualities of aluminium.

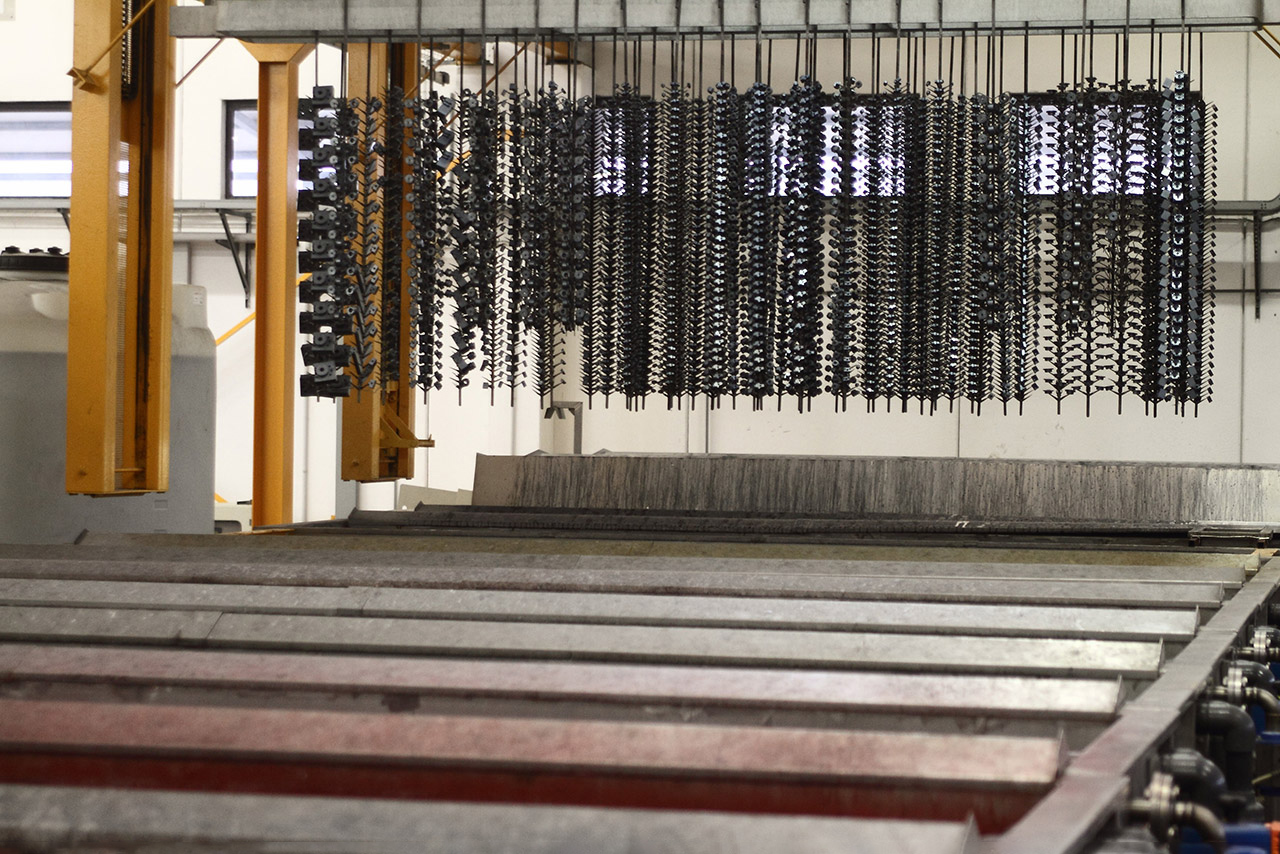

Our plants

New Oxidal

in Brescia

Quality and innovation of our treatments are guaranteed by two modern automated and multifunctional systems monitored through dedicated software.

In the two modern plants in Brescia, New Oxidal develops new technologies for the treatment of aluminium, magnesium and other alloys, by optimizing the energy consumption and reducing emissions.